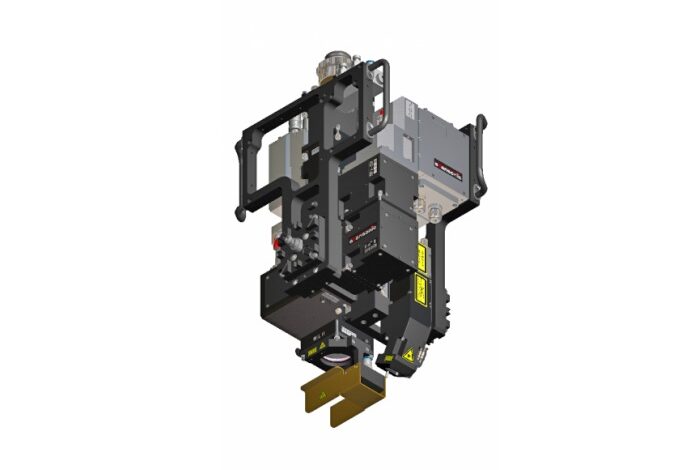

RLW-A | Reduced cycle times with contactless seam tracking

The RLW-A sets new standards in contactless fillet welding and enables overlap joints to be replaced by fillet welds. This reduces joint flanges and requires less laser energy for the same seam cross-section. The processing optics ensure precision, dynamics and reproducibility along with cost-effective operation.

Function description

The RLW-A system combines optical seam tracking with scanner axes. During the robot movement, the system measures the joint and controls the highly dynamic scanner levels online. Measuring precision is ensured by the patented coaxial guidance of laser beam and measurement light in the same optical system. The position of the laser spot remains precisely on the joint. This makes remote fillet welding possible on 3D body-in-white components.

Areas of application

-> Laser welding

-> Fillet welds e.g. on attached assemblies (doors, decklids, etc.), A and B pillars, front/rear bumpers, door sills, roof, and vehicle underbody.

-> Fillet welds on T and lap joints, open edges.

-> Adjustable offset defines overlap seams to the abutting edge

-> On-the-fly pattern welding of lap joints.

Advantages

A. Fillet welds enable reduction of flange lengths in vehicle construction.

B. Lower weight reduces fuel consumption and CO2 emissions.

C. Large working distance allows overrunning of clamps and fastening fixtures in the process, significant reduction in cycle time compared to tactile systems.

D. Application-specific scan fields for significant reduction in consumption costs.

E. Simplified operating concept with all laser process parameters set via the RLW-A GUI and controlled/regulated by the RLW-A controller.

F. Spot size is adjusted via autofocus and kept constant during the process using the seam-tracking values.

G. Combination tool for high-productive welding of fillet joints as well as for pattern-welding.

Properties

1. Robust seam tracking.

2. Easy parameterization of seam tracking through separate parameteriziation software (GUI)

3. Simple parameterization of welding patterns using geometry parameters.

4. Plug & Play processing system – an autonomous system with a simple robotics communication – no complex sensor-robot interface is require.

5. No relearning of path programming necessary – based on standard welding optics.

6. Scanners with highly dynamic adjustment reaction up to 1000Hz.

7. Thanks to the configurable modular design, the customer can choose the functions that he needs for his production

Supported Laser

– Fibre laser

– Disk laser