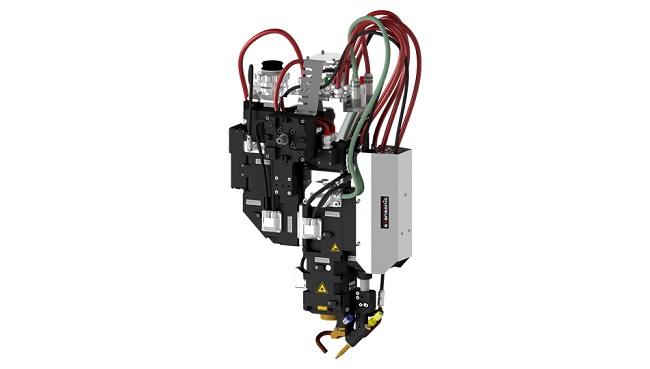

The world’s most frequently used optic for laser welding. With its patented tactile seam tracking technology, the laser processing system enables perfect seams in the visible operating range and makes post-processing unnecessary. Customers across the globe – especially vehicle body manufacturers – rely on the ALO3.

Function description

The tip of the filler wire precisely detects the weld edge and safely guides the joining process along the seam. Component tolerances are automatically compensated. At the same time, the wire itself is part of the brazing and welding process

Areas of application

1. Laser brazing and welding

2. Steel and aluminum

3. Y-seam at flange welds

4. Fillet weld at the lap joint

5. Fillet weld at the T-joint

Advantages

A. Stable process control and high-quality seams because workpiece deviations are automatically compensated.

B. Small radii and 3-D contours can be sensed easily (more design freedom)

C. No advance-tracking compensation required

Properties

– Customised customer-specific scapacs®modular systems can be configured for any standard laser source.

– Precise, force-controlled seam tracking with tactile sensor using a filler wire

– Lateral swivel range (Y) +/-90 degrees

– Height of operating range (Z): +/-5 mm

– User-defined adaptation to robotics

– Configuration via Ethernet

– Integrated cross-jet

– Integrated safety-glass drawer with quick-change function

– Wire feed connection compatible with various manufacturers

– Service-friendly construction

Supported Laser

A. Diode laser

B. Solid-state laser like rod laser, disk laser, fibre laser