Remote Laser Welding Application for Car Side Door

In the field of Automotive Engineering, each component has its own significance and purpose.

Every curve, line and components are result of deep analysis and engineering so as it plays vital role in various mechanisms which are linked to each other and form the vehicle as a whole which is capable of serving its purpose of transport and traveling. There are many minute aspects which are taken into consideration, and each of these aspects has influence on car performance.

One of these integral aspects of this assembly is the car door.

Car Doors:

Car doors consist of intricate assemblies of Window glass, locking mechanisms, hinges, panels, And many such components. All of these components are assembled together to form a car door.

A car door is exposed to various stresses and impacts, like vibrations, weather conditions, frequent opening and closing, etc. They must withstand all this and also, serve their main purpose of creating a comfortable and safe cabin space for the passengers.

To fulfill this purpose, the components of car door must be securely joined, and the joint must be strong enough to keep the assembly impact even after all impacts and stresses. For this, an efficient joining process is necessary.

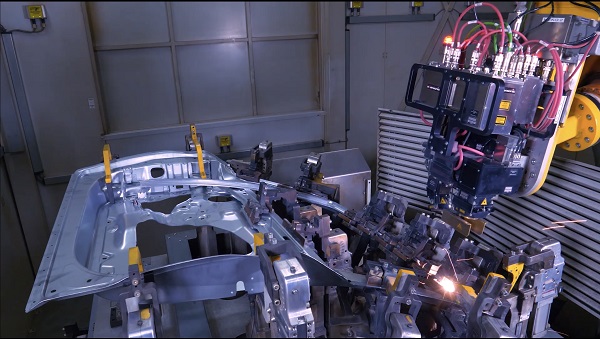

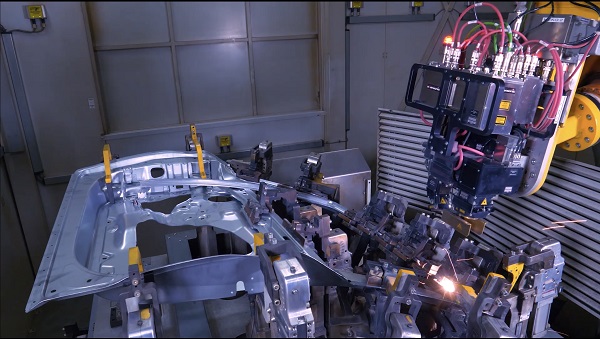

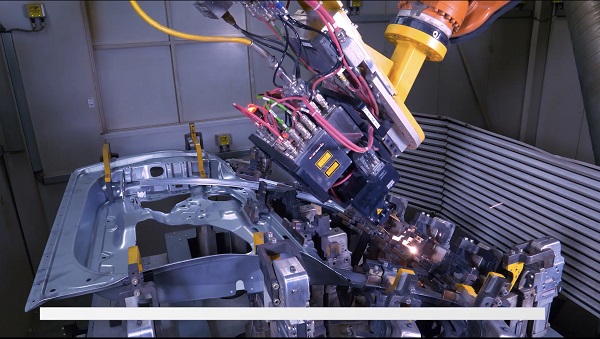

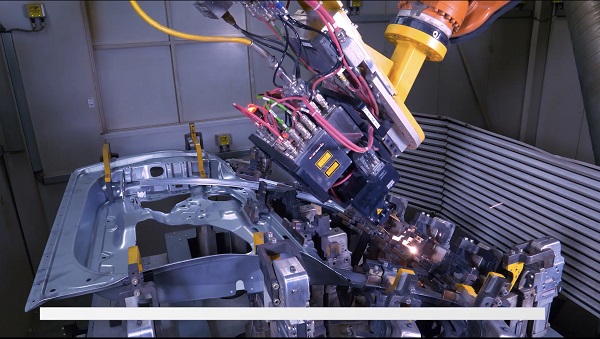

- Remote Laser Welding is Non-Contact Type Scanner based welding process.

- The system basically consists of a Laser source which generates the beam, and scanner-based optics which controls the beam motion using fast moving mirror mechanism. This is integrated with robots, fixtures and suitable automation according to what the system demands.

Quality Matters: Meeting the Criteria with Remote Laser Welding

When speaking of widely used crucial commodities like automobile, safety and performance are the things which cannot be compromised. Therefore, there are some criteria which must be satisfied, and it is very necessary that for this, an appropriate manufacturing process is selected:

1. Accuracy: Car doors consist of complex assemblies and require high accuracy and precision. Laser Welding, which uses highly concentrated beam, enables precise control over the process, ensuring fine and clean seams which not only give accuracy and precision but also contribute to functionality and visual appeal.

2. High weld strength: For the car door to withstand frequent impacts and various stresses and provide a safe cabin to the passengers, the joints must be strong enough. Laser Welding, which uses focused beam to rapidly melt, and fuse the components leads to fine microstructure which results in strong weld.

3. High Speed Welding: As the beam motion is controlled by fast moving mirrors, remote welding process is much faster than normal welding process.

4. Higher working distance: Welding Car side door assembly requires fixtures with complex shapes, which can create obstacles in the welding process. Remote Laser Welding enables welding with higher working distance, i.e welding can be done, keeping optics at a higher distance from the component, thus eliminating obstacles and facilitating smooth welding process.

5. On the fly processing increases the overall speed, allowing to weld two to five welds in a second and thus, enhancing the productivity.

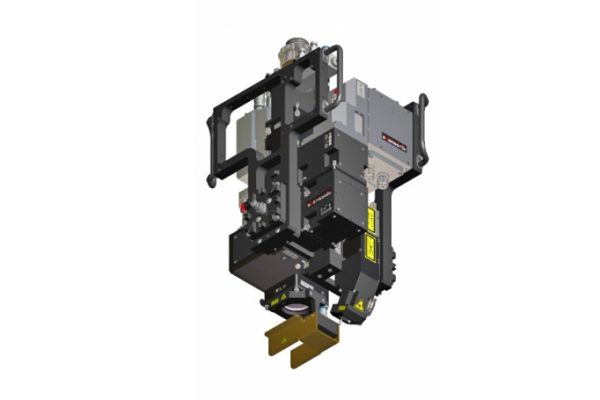

Introducing the Scansonic RLW-A Optics:

Optics is a very important and crucial part of any Laser based system. The quality and effectiveness of the process highly depends on the optics, so it is very necessary to choose an appropriate optics for any Laser process.

We bring forward to you, Scansonic RLW-A Optics:

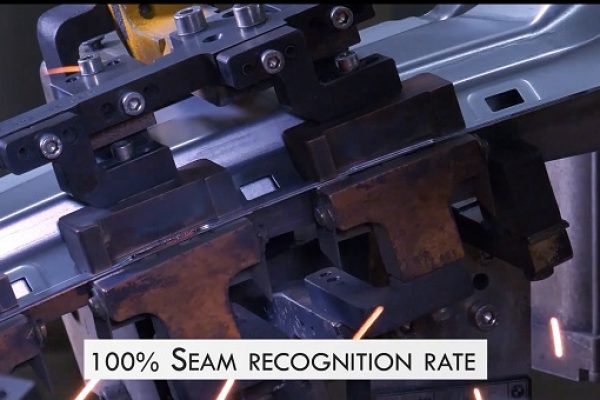

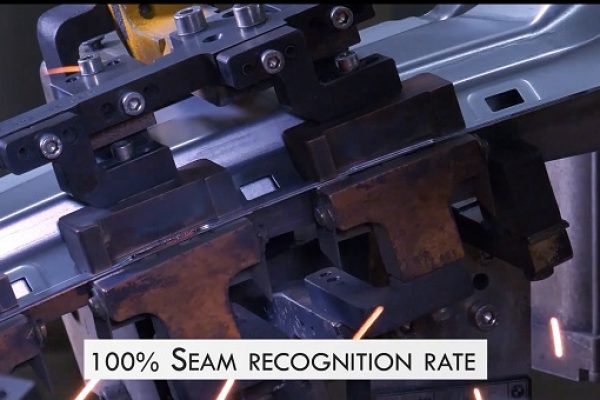

- This RLW-A Optics uses the principal of Remote Laser Welding in which the Laser beam is guided by fast moving deflection mirror mechanism. This mechanism controls the path of the beam.

- This is particularly useful for welding complex geometries.

- The RLW-A integrates this with the Optical Seam Tracking technology, which tracks the path of the weld seam and facilitates the welding process with high precision and accuracy.

- Seam tracking enables replacement of overlap joints with fillet, which reduces the laser energy input required for the Same cross section.

- This also saves a lot of material.

The RLW-A sets a new standard in contactless welding applications. This advanced processing optics ensures precision and reproducibility along with cost effective operation.

Conclusion:

As we glide our fingers along the smooth edges of car doors, we are experiencing the result of precision engineering and meticulous welding. Laser welding, coupled with optics like Scansonic RLW A, elevates these components from mere functional necessities to symbols of automotive craftsmanship.

It’s a fusion of technology and artistry that propels us forward, reminding us that every detail matters in the pursuit of automotive excellence.