What is Laser Seam Tracking & Types of Seam Tracking

With increasing demand for more productivity and accuracy, Welding processes are being automated. In many factories and production plants, welding processes are fully automated and everyday, more industries are adapting fully automated systems. For these systems to have quality, accuracy and precision, there needs to be some facility or technology that accurately detects the joints/seam profile and feeds it to the system so that welding can be done precisely, and with minimal human intervention.

The sensor detects the seam profile and joints and the data is sent to the automated welding system (robot / CNC/ etc.) and the welding operation is performed accordingly. This tracking operation is done in real time.

There are two categories in seam tracking depending on the method of tracking:

TACTILE SEAM TRACKING

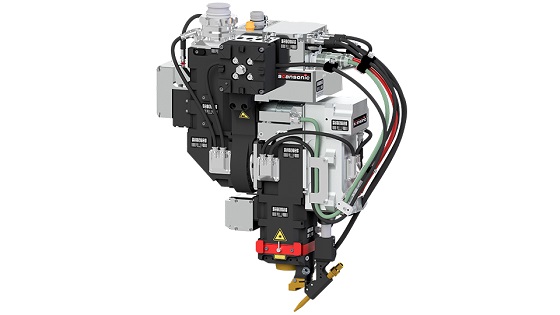

Tactile seam tracking is used in Brazing applications and similarly, in welding applications with filler material. In Scansonic ALO4 optics which is specifically designed for Laser Brazing and Welding, the filler material wire acts as the tactile sensor. The wire tip is in constant contact with the seam and senses the profile throughout the operation. The swivel axis offers 90 degrees of swivel angle and the wire continuously adjusts its position according to variations in seam profile to maintain contact of the tip with seam and it is melted by the laser focal point. This mechanism guides the head precisely over the seam profile. This gives high accuracy and precision.

OPTICAL SEAM TRACKING

In this process, the seam tracking is done without any actual physical contact. The Scansonic TH6D sensor uses triangulation to scan the seam shape. There are 3 laser lines which give excellent measurement stability. All the data like joint edge offset, gap dimensions, position of tools relative to the workpiece is transmitted to the robot controller.

This process works even with highly reflective surfaces like stainless steel and Aluminium.

ADVANTAGES OF SEAM TRACKING:

- Normally, in the robotic welding process, if a complex seam profile is to be welded, the operator has to teach the complex path to the robot.

- To teach a complex path to the robot, a lot of reference points need to be fed to the robot.

- By default, any robot system is programmed in such a way that when traveling from one reference point to another, the system chooses the optimum path. This optimum path may not accurately match with the seam profile, so, for more accuracy, more reference points should be fed. It is a very tedious process and does not ensure accuracy.

- Seam tracking technology eliminates all of this. With seam tracking technology, all we need to do is teach the starting and ending point of the seam to the robot and all the complex paths will be tracked by the system, there is no need for reference points in between.

- It saves a lot of time and makes the process significantly easier. Also, it increases the accuracy of the process.

- This enhances the productivity and efficiency of operation.