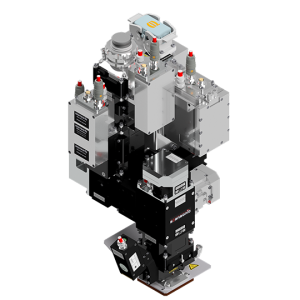

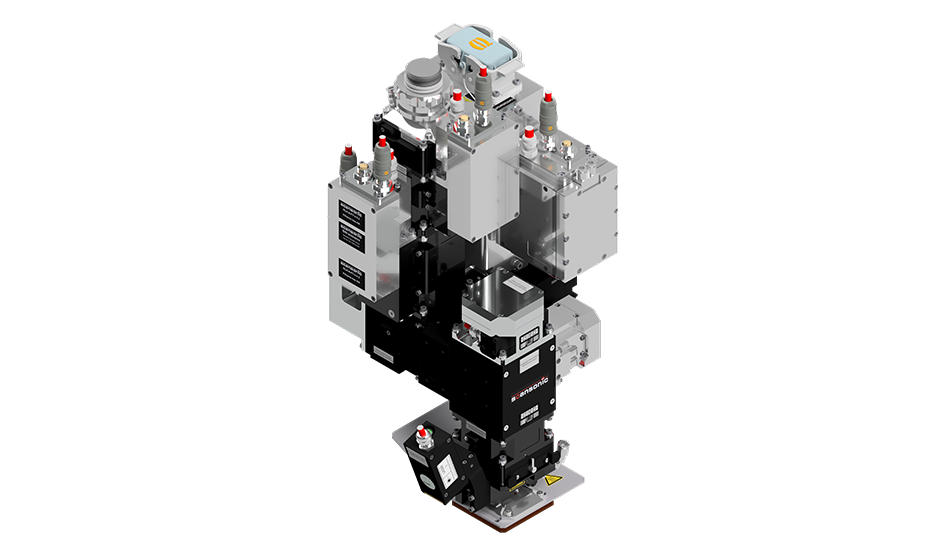

Remote Laser Hardening RLH - A by Scansonic

Similar to Remote Laser Welding, Remote Laser Hardening operates on the principle of fast moving deflection mirrors to control the Laser beam.

This gives more flexibility to the beam path and any components with complex intricate geometry can be hardened by modification of spot geometry according to the component profile.

Conventionally, for components of different profiles, to get corresponding spot size, different optics were required.

But this single RLH-A optics can do all of that without any need for different optics.

ADVANTAGES OF REMOTE LASER HARDENING :

The energy concentration is precise and controlled so only that portion is hardened which is necessary.Selective hardening of workpiece, especially on complex geometries like curves, holes, etc. avoids unnecessary excessive heating and thus preventing defects like warping, thermal distortion, etc

In conventional hardening, heat input is much more. So, even though we get the desired hardness, the HAZ are more . The remote hardening process, being precisely controlled, is a good method for case hardening. If we only want to enhance wear and abrasion resistance, hardening up to few hundred micron depth is sufficient and it can be precisely done by RLH. The core layers underneath retain their ductility and toughness. So, we have a material which is resistant to wear and tear, as well as tough enough to withstand impact.

In the Remote Laser Hardening process, Temperature is measured continuously during the process by pyrometer, and a feedback system maintains precise control over the Temperature. So, there is no overheating and melting, and also, the problems which are caused due to insufficient heat input are also solved.

Product Details

Scansonic RLH - A

The RLH-A offers real advantages when it comes to remote laser hardening of intricate component structures. It enables process-reliable hardening depths in the 0.1-millimeter range along with a variable design of the spot geometry. Individual material surfaces can be hardened selectively with contour accuracy – all with a single processing optic. In the past, different optics with corresponding spot shapes were required for different components. Now, the RLH-A handles every hardening task.