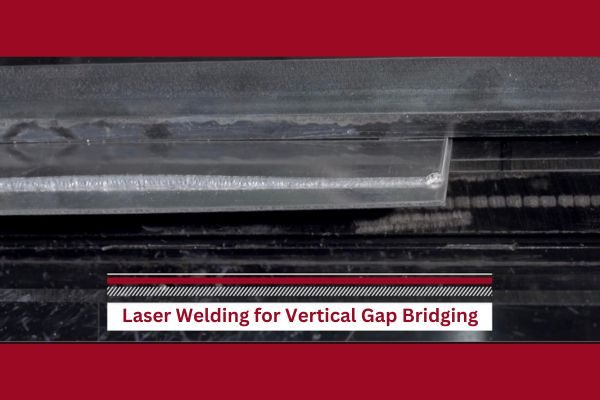

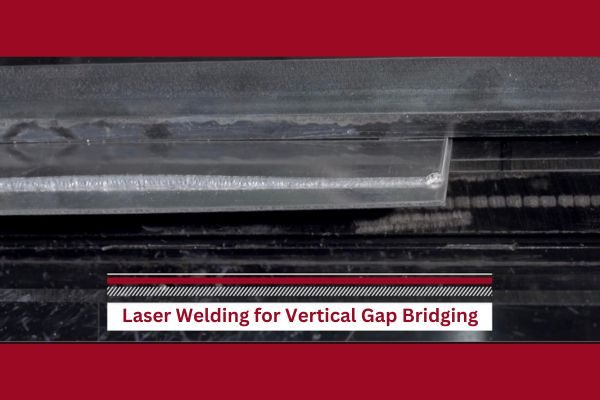

Laser Welding for Vertical Gap Bridging

In Laser Welding, or of the most basic pre-requisite is zero gap condition. I.e there must be absolutely zero gap between the two surfaces to be welded. If this condition is not fulfilled, it might leave some air gaps and affect the weld quality.

So, lot of precautions are taken to achieve this zero-gap condition. Part specific fixtures need to be designed and manufactured for the application.

Introducing the advanced Scansonic RLW – A optics:

The new RLW-A has proven to be a game changer in the Laser Welding process.

It enables overlap joints to be replaced by Fillet joints.

It is integrated with optical seam tracking technology which helps to detect gaps on the fly.

Vertical Gap Bridging:

- The RLW-A is integrated with optical seam tracking sensor TH6D, which helps detect the gap on the fly.

- The RLW-A optics is based on fast moving deflection mirror mechanism, which gives greater, precise control over the beam.

- This mechanism enables the oscillation of beam between the upper and lower edge of the fillet joint, thus directing the flow of weld pool, so as to bridge the gap between two edges.

- Vertical gaps can be bridged with this advanced technology.

- This eliminates the need for designing complex fixture for achieving zero gap condition, saving lot of time and also reducing the operational expenses.

- Gap Compensation gives better quality, fault proof, superior weld.

See the below video for more clarification.