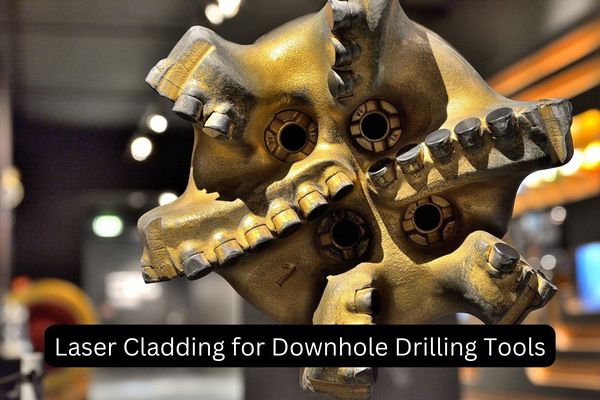

Laser Cladding for Downhole Drilling Tools

Challenges

Down hole drilling tools are extensively used in the oil and gas industry.

Ideally the down hole drilling tools should last longer and give reliable performance under harsh working conditions such as abrasion, corrosion and should not wear out easily.

If there is any breakage or failure of tools, maintenance downtime hampers the production and also results in increased cost for repairing or replacing such high value components.

Laser Cladding/ Laser Metal Deposition is the Solution

In the laser cladding process the down hole drilling tool is given a coating of another material with higher abrasion / corrosion resistance to enhance the working life of the tool.

Laser cladding has significantly lower and localized heat input in comparison to conventional hard facing processes such as MIG, TIG or PTA. This results in very low dilution and minimal or no deformation in the part after cladding. Most of the time the part can be used as it is after laser cladding without the need for remachining or finishing.

Most important is that the bond formed between the clad material and drill tool surface is metallurgical, so unlike mechanical bonds, this coating surface does not chip off easily and it is durable and long lasting.

Generally the drill tools are coated with a very hard Tungsten Carbide (in a nickel based matrix) coating layer which significantly enhances the tool’s resistance to abrasion , this increases its working life, bringing down the maintenance down time and repair costs.

Also laser cladding can be performed on a variety of base materials (and geometries ) commonly used in the oil and gas industry such as low alloy steel, non-magnetic steel, Carbon steel etc. Even difficult to weld materials such as Inconel based alloys can be easily cladded with a laser.

Laser cladding has now become the standard for hardfacing of the below mentioned downhole drilling tools such as:

- Stabilizers

- Tricone bits and drill heads

- Drill collars

- Mud motor parts

- Wear bands

- Ball valves and seats

- Radial bearings

Any queries ? Feel free to contact us.

Laser Cladding Machine

Laser power upto 10 kW (as per requirement)

Linear track

Robot with 7 motion axes.

Powder feeder

Chiller

UPS

Work table