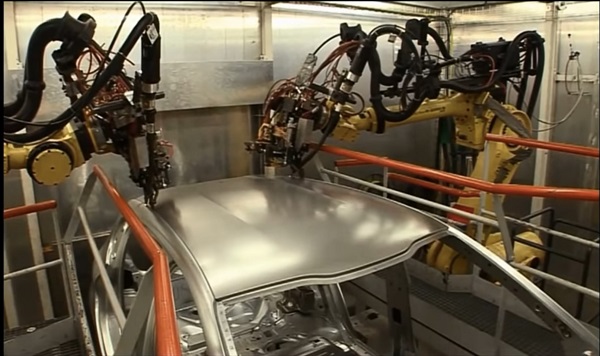

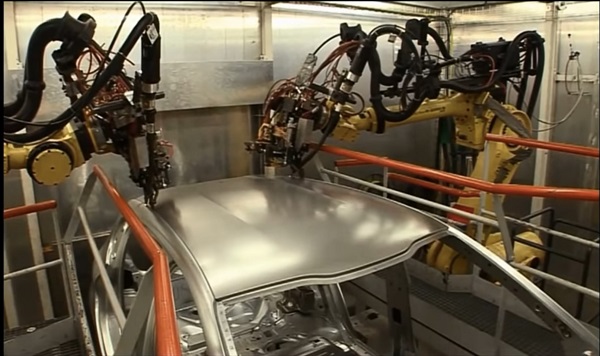

Laser brazing in automotive industry for Rooftop

In the field of automotive, the role of each component goes beyond mere basic functionality. Each part must fulfill the safety and performance requirements. Roof top assembly of a car is one of such crucial assemblies which consists of two main components, the chassis which is the basic foundation of the car body, and the roof which needs to be joined with the chassis.

It is a dynamic juncture, where chassis and the roof coverage converge, which shapes the car’s structure and aesthetics.

The rooftop assembly has to withstand different impacts, from high wind resistance, to rainstorms, various other environmental, as well as mechanical factors which include vibrations and rigors of the road, and also maintain the vehicle’s aesthetic appeal. This demands an efficient joining method for joining the roof top to the chassis.

Laser Brazing: Crafting the perfect bond

Laser Brazing – A technique that harnesses the power of light to create a seamless, strong joints. It is similar to Laser Welding, the only difference being that, instead of the material surface, only the filler material is melted, which bridges the gap between chassis and roof, resulting in a bond, that not only fulfills the strength criteria, but also keeps it aesthetically pleasing.

Meeting the criteria: Precision and Durability

The chassis and roof top assembly must withstand various impacts, and for that, they must fulfill certain criteria. The choice of manufacturing process, i.e the joining method plays a very crucial role in this.

Strength and stability: Laser Brazing, using a high-power industrial Laser, utilizes a filler material which has a melting point below that of the base material. The focused energy of the Laser beam rapidly heats base material and melts filler material, causing filler material to flow through the joint. The precise control of Laser beam helps to minimize overheating and distortion, resulting in a more precisely controlled process. The filler material and the base materials form a metallurgical bond, and when it solidifies, as a result we get a strong and durable bond.

Aesthetic and seam: As the process is precisely controlled, the thermal stresses and distortion are minimal, the seam is fine and smooth which enhances vehicle’s visual appeal.

Process Efficiency: In industries, such as automotive, production efficiency is very essential. And production efficiency is highly dependent on process efficiency. Laser Brazing is highly energy efficient process, as the energy input is highly focused, the required input is low, so the process is efficient.

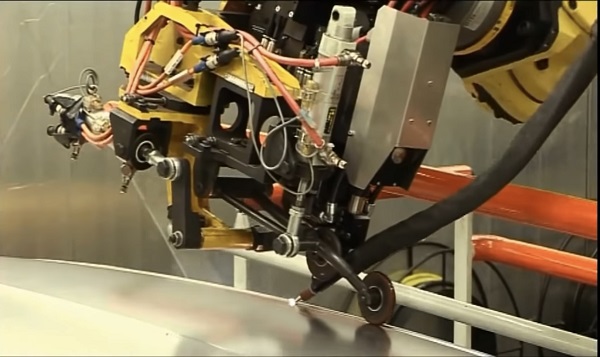

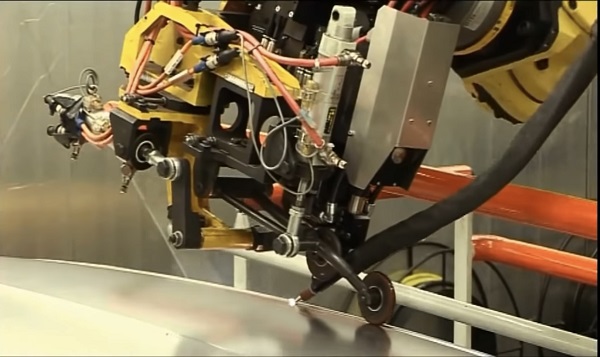

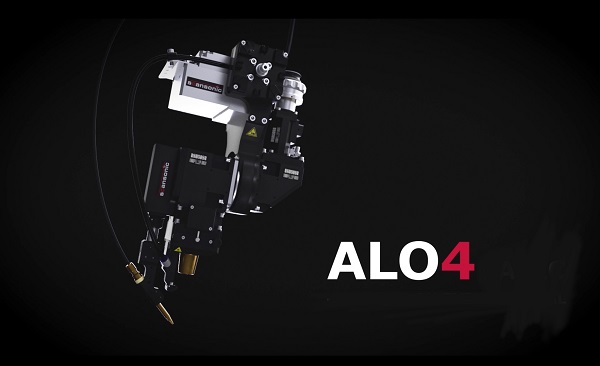

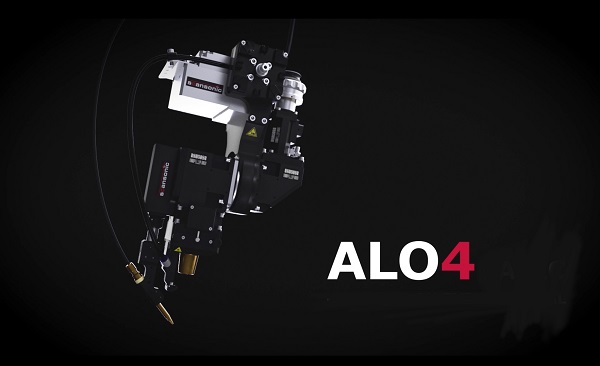

Scansonic ALO4: Pioneering Perfection:

ALO4 is a brazing optics developed by Scansonic for such high-power industrial applications.

Its advanced features give it leading edge in the field:

Tactile Seam Tracking:

The filler material wire is continuously pressed against the joint, and acts as a mechanical sensor. It senses the seam profile throughout the operation.

90-degree swivel axis:

The 90-degree swivel axis helps the processing head to move flexibly as per the profile of the seam, thus making the operation easier.

Auto Focus:

The profile of the seam over roof and chassis is not straight. It has a slight curvature among the vertical plane, for engineering design, as well as aesthetic purposes. ALO4 optics has auto Z axis focus feature, so the optics automatically adjusts the focus according to the curvature, preventing the deco using of the laser beam from profile, and maintaining it within the focal position, and this helps to get perfect joint.

Conclusion:

As we admire the seamless design of modern automobiles, it is the result of this highly engineered process. Rooftop Brazing, empowered by Laser technology and sophisticated Scansonic ALO4 Optics stands a testament to relentless pursuit of automotive excellence. With each rooftop assembly meticulously joined through Laser brazing, we experience the intersection of engineering innovation and artistry, shaping the vehicles that navigate the roads of our future.