What is mean by Laser Beam Profile & Types of Laser Beam Profile

Laser is a modern advanced technology and it provides very powerful tools in a wide range of applications like manufacturing industries, mining , automotive, etc. However, Laser beams have different properties, shapes, and beam profiles. Depending on applications, different beam profiles are suitable for different uses.

Two of the most popular and commonly used beam profiles are Gaussian profile and Top Hat beam profile. Let us look at these beam profiles and which applications are they suitable for :

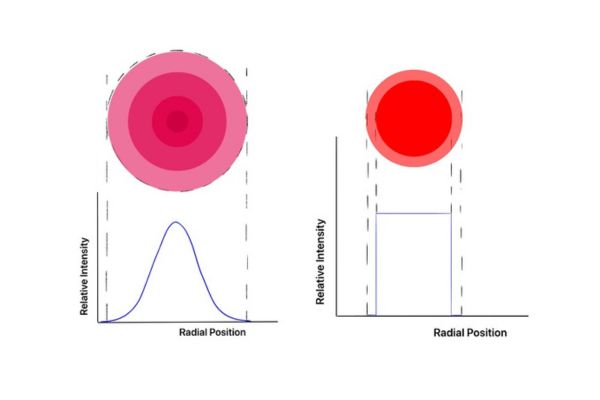

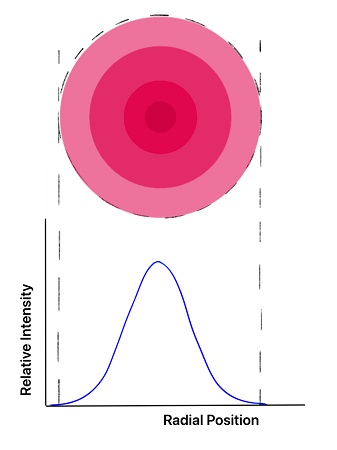

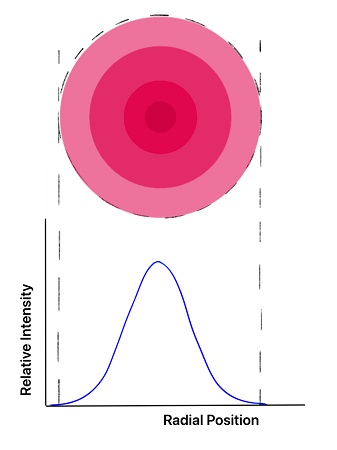

Gaussian Beam Profile:

Beams with these profiles have maximum / peak intensity at the centre, and it tapers off towards the edges. Imagine a beam of light like a gentle hill, which rises at the centre and gradually falls towards the edges. To get more clear idea, have a look at below image :

Characteristics of Gaussian beam:

- Most of the beam energy is concentrated at the centre peak of the beam

- Energy intensity decreases as we move away from the centre

- This beam profile is suitable for applications where precision in important

For eg: Keyhole Laser Welding, Laser Cutting, Laser Marking and engraving.

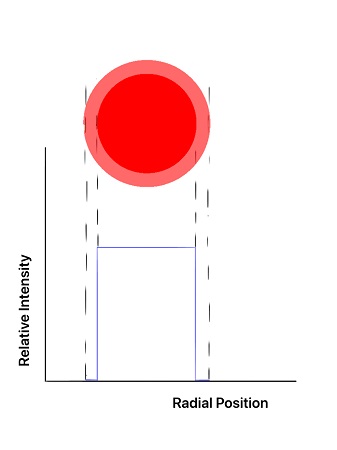

Top Hat Beam Profile:

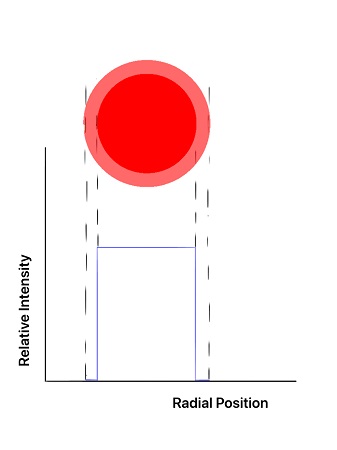

It is also known as flat top beam profile. It has uniform intensity across the center, like a flat hat. Imagine a beam that is like a hat. The intensity remains fairly uniform within a larger portion from the central region, and then drops off at the edges, creating a hat-like shape. To get more clear idea, refer to the below image :

Characteristics of Top Hat Beam are:

- Central region of beam has relatively uniform and constant intensity

- Intensity suddenly drops down at the edges of the flat region

- It is suitable for applications where uniform distribution of power is necessary

For eg: Laser Cladding, Laser Surface treatment methods, Heat Conduction Welding, etc.

APPLICATIONS:

Different processes have different requirements and accordingly, the beam profile is chosen for the process. Here, we will look at some processes and which beam profile is suitable for the process and why :

Laser Welding:

According to requirements, Laser Welding can be done in 2 ways : Keyhole/ Deep Penetration welding and Heat Conduction welding.

Depending on spot size and application specific requirements, either Gaussian or Top Hat beam can be used for Laser Welding.

Laser Cutting:

Laser Cutting needs focused energy intensity for precise and clean cuts.

A top hat beam profile is less focused and more distributed , so it is not preferred for this application.

A Gaussian beam provides focused intensity required for precise cuts, so it is more suitable for Laser Cutting.

Laser Cladding:

In Laser Cladding, a base material is given a coating of another material to enhance its surface properties.

To require desired output, it is necessary that the coating material should be uniformly cladded over the surface, i.e the material deposition should be consistent across the workpiece.

It is important for the uniform thickness and material properties of the cladded layer.

For this purpose, Top Hat beam profile is more suitable because of its uniform distribution of intensity over the beam profile.

Laser Hardening:

Laser Hardening is a surface modification method used to enhance surface hardness of material, by rapidly heating the material, and then self quenching.

It requires uniform heating of the surface.

In such cases, if a Gaussian beam is used, which has higher energy concentration at the centre, it might lead to uneven heating and cause variations in hardened layer’s depth over the workpiece and might not give desired results.

So, top hat beam profile, which has uniform intensity distribution which ensures uniform heating, and uniform hardening is preferred for this application.

CONCLUSION:

Clarity about different beam profiles helps us harness the power of Laser technology for various applications. Both beam profiles, Gaussian as well as Top Hat beam have their own advantages and characteristics.

However, while choosing a beam for a particular application, it is better to approach experts who can study the application in depth and choose an appropriate beam profile suitable for the application.