Advantages of laser in Aluminum Welding

IMPORTANCE OF ALUMINUM

Aluminum and its alloys find use in various industries like automotive, aerospace, electronics and many other fields. This is because some of its desirable properties such as

Electrical and thermal conductivity

Light weight due to low density

Easily recyclable without loss of desirable properties

It has high corrosion resistance

Aesthetically attractive

CHALLENGES IN ALUMINUM WELDING

Aluminum can be difficult to weld due to following reasons:

Due to high reflectivity and thermal conductivity Aluminum reflects most of the light and heat incident on it , so it is difficult to melt aluminum and weld it.

The weld quality can be poor and inconsistent due low viscosity of molten aluminum as well as low boiling point of alloying elements

There are problems related to alteration and degradation of properties and formation of solidification and liquation cracks.

Also, there are problems like porosity caused due to oxidation and hydrogen contamination during storage and weld

ADVANTAGES OF LASER IN ALUMINUM WELDING

Lasers are perfectly suited for welding of aluminum due to exceptional beam quality , precise control over power going into the material and repeatability .However to successfully weld Aluminum with lasers some precautions need to be taken :

Cleanliness of the part being welded is of utmost importance because contaminants and hydrogen intake during welding are one of the main causes of porosity in the weld.

The weld surface must be cleaned to remove the surface oxide layer if any as well as any surface debris,dirt etc before doing laser welding.

Its advantageous to use shielding gas during welding to keep the weld pool free of contamination.

Some of the aluminum alloys such as 6xxx series are prone to cracking , it is appropriate to use filler material to reinforce the joint properties as well as reducing / eliminating cracking. Proper design of joints is helpful in reducing the crack tendency of aluminum weld.

Some recent advances in laser beam shaping such as spot in spot and beam oscillation are helpful in reducing/elimination of cracks and porosity giving a very reliable weld joint.

Any queries ? Feel free to contact us.

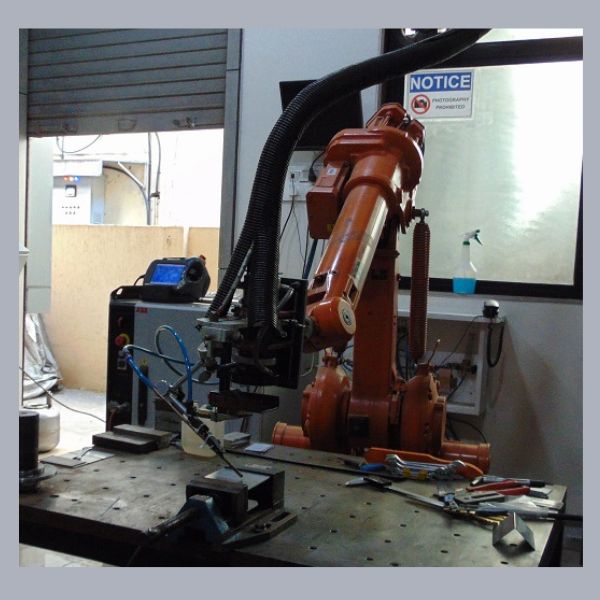

Fiber Laser Welding Machine

Laser Source : Fiber Laser / Diode Laser Power 1KW Plate thickness 600 microns Materials MS, SS Work Area 750(X) x 280(Y) x 200(Z) (mm) Total axes 3 (1 linear and 2 servo) Application dependent customized solution

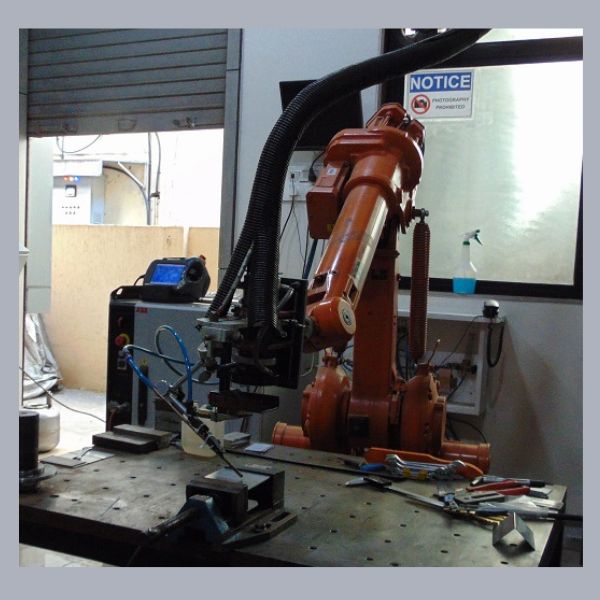

Laser Welding Machine for Aluminium

Technical Spec: Power: 3 kW to 60 kW Laser source: Fibre and Diode Weldable Aluminium grades: 6000 series of Al alloys with filler material 4032 Al or 4047 Al.